Discover Just How Membrane Switches Function and Their Role in Modern Electronics

Membrane Switches stand for an advanced assimilation of innovation and design within the realm of modern electronic devices, serving as necessary user interfaces in numerous tools. Understanding the details of Membrane button functionality and their wider effects in enhancing customer experience welcomes additional expedition into their style, benefits, and the innovative advancements forming their future in technology.

What Are Membrane Buttons?

Membrane switches are differentiated by their longevity and resistance to ecological factors, such as dust, wetness, and extreme temperatures. They can be personalized with numerous graphics, shades, and responsive responses alternatives, boosting customer experience while keeping aesthetic charm - membrane switches. In addition, the incorporation of printed circuits enables seamless integration right into devices, boosting total capability.

The convenience of Membrane buttons is noticeable in their capacity to support both complicated and easy control functions. They can incorporate features such as LED indications and touch-sensitive modern technology, satisfying specific customer demands. As modern technology continues to evolve, Membrane Switches remain vital for enabling effective and user-friendly customer interfaces, thereby playing a pivotal function in the advancement of contemporary digital gadgets.

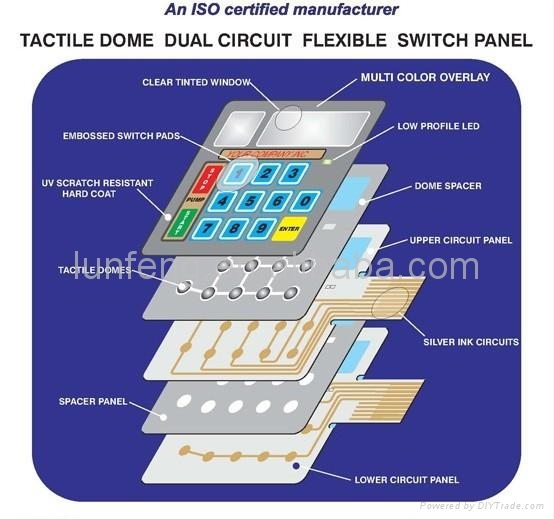

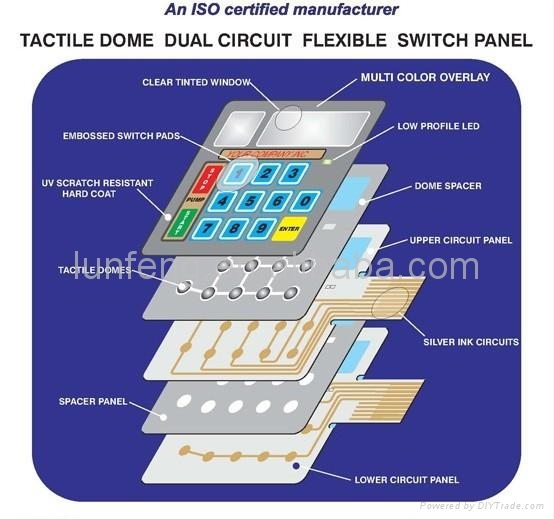

Components of Membrane Buttons

Membrane switches are composed of several vital parts that work together to develop a reliable and useful interface. The primary elements consist of the visuals overlay, adhesive layer, spacer layer, and conductive traces.

The graphic overlay functions as the user interface, normally published on a versatile substratum such as polyester or polycarbonate. This layer not just offers aesthetic charm however also consists of responsive feedback, visual cues, and safety features. Below the graphic overlay lies the glue layer, which protects the button to the gadget and ensures sturdiness against environmental anxieties.

The spacer layer is critical for keeping the required void between the visuals overlay and the circuit layer. This gap permits the activation of the button when pressure is used. The conductive traces, generally made from silver or carbon, form the electric paths that complete the circuit when the button is involved.

In addition, a backing layer might be consisted of for structural assistance and insulation. These elements work together perfectly, guaranteeing that Membrane buttons are both durable and straightforward, making them essential in different modern-day electronic applications.

How Membrane Switches Work

Exactly how do Membrane Switches function properly within electronic gadgets? Membrane Switches operate on the concepts of pressure-sensitive innovation, utilizing a split construction that consists of graphic overlays, adhesive layers, and conductive aspects. When a customer applies pressure to the button, the leading layer warps, enabling the conductive aspects under to make get in touch with and finish an electric circuit. This activity causes the desired function within the tool.

The style of Membrane buttons is important for their efficient procedure (membrane switches). The layers are thoroughly crafted to give responsive responses, durability, and resistance to environmental aspects such as wetness and dust. The incorporation of domes-- tiny, increased locations within the switch-- improves tactile reaction, supplying customers with an obvious click experience upon activation

Furthermore, Membrane buttons can be tailored in terms of size, form, and graphics, making them suitable for numerous applications. They are often utilized in control panels, clinical gadgets, and consumer electronic devices because of their sleek design and dependability. Overall, the their explanation reliable functioning of Membrane switches is critical in enhancing individual interaction and ensuring seamless procedure in modern-day digital tools.

Applications in Modern Devices

Utilizing their special layout and capability, Membrane buttons have actually become essential elements in a vast array of modern electronic gadgets. These flexible user interfaces are utilized in customer electronic devices, commercial devices, clinical gadgets, and auto controls, giving smooth customer communication.

In customer electronic devices, Membrane switches are typically discovered in home appliances like microwaves, washing devices, and other household tools, where they allow user-friendly control with a smooth profile. Their low-profile layout promotes assimilation right into small gadgets, enhancing aesthetic allure without endangering capability.

In commercial applications, Membrane Switches work as control panels for machinery, offering resilience and resistance to harsh environments. Their capacity to hold up against dampness and pollutants makes them perfect for use in production and handling industries.

Clinical gadgets also take advantage of Membrane switches, which are made to be simple to clean and maintain, making certain hygiene in clinical setups. They are typically used in analysis devices, patient surveillance systems, and portable clinical gadgets, where reliability is extremely important.

Advantages of Membrane Switches

Among the essential benefits of Membrane switches is their versatility, which enables them to be tailored for a range of applications across several you can look here industries. These buttons can be designed in different shapes and dimensions, accommodating special product needs while offering smooth integration right into devices. Their thin account enables a sleek and small style, frequently boosting the aesthetic charm of digital products.

One more substantial benefit is their toughness - membrane switches. Membrane switches are commonly resistant to dust, dampness, and chemicals, making them perfect for rough environments. This durability expands their lifespan compared to standard mechanical buttons, reducing the requirement for constant substitutes

Additionally, Membrane Switches deal cost-effectiveness. The production procedure involves printing modern technologies that minimize manufacturing prices, particularly for big runs. This price, combined with low upkeep needs, makes view it now them an appealing option for makers.

Conclusion

In conclusion, Membrane Switches represent a significant development in interface innovation within contemporary electronics. Their layered construction, pressure-sensitive operation, and adaptability to various applications underscore their importance across multiple sectors. The sturdiness and environmental resistance of Membrane Switches further enhance their allure, making them a recommended selection for makers seeking trustworthy and adjustable solutions. As the demand for resistant and user-friendly interfaces remains to expand, the function of Membrane buttons fit individual experience will unquestionably broaden.

Membrane Switches stand for an advanced integration of modern technology and style within the world of contemporary electronics, serving as crucial user interfaces in many tools.In the realm of contemporary electronics, Membrane Switches offer as vital components that assist in customer interaction with tools. As technology proceeds to evolve, Membrane Switches remain crucial for enabling effective and intuitive individual interfaces, therefore playing a critical function in the innovation of modern-day electronic gadgets.

Just how do Membrane Switches feature properly within electronic gadgets? On the whole, the efficient functioning of Membrane buttons is pivotal in enhancing individual communication and ensuring seamless procedure in modern-day electronic devices.